O nas

Firma Akrostal istnieje od 2000 roku i jest jednym z czołowych polskich dystrybutorów stali jakościowych. Cały asortyment, składający się z ponad 1500 pozycji, magazynujemy w halach o powierzchni ponad 10 000 m2. Ponadto, dysponujemy magazynem przeładunkowym w Sosnowcu oraz w Ostrawie (Czechy![]() ).

).

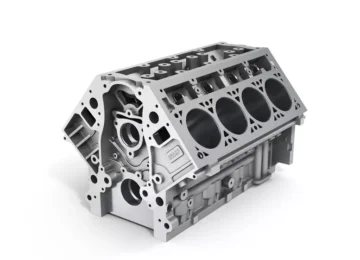

Na naszą ofertę składają się:

- stal narzędziowa do pracy na zimno

- stal narzędziowa do pracy na gorąco

- stal do obróbki cieplnej

- stal do azotowania

- stal sprężynowa

- stal do nawęglania

- stal węglowa

- stal konstrukcyjna

- stal trudnościeralna

- stal szybkotnąca

- stal nierdzewna

Na życzenie Klienta jesteśmy gotowi sprowadzić również inne gatunki stali.

Posiadamy nowoczesny park maszynowy dzięki czemu możemy świadczyć usługi z zakresu obróbki metalu.

Wśród naszych odbiorców znajdują się największe firmy spośród takich gałęzi gospodarki jak przemysł lotniczy, samochodowy, armaturowy, stoczniowy, rolniczy oraz odlewniczy.

Asortyment w PDF

Co nas wyróżnia

Szybkość

45 pił taśmowych i 22 suwnice obsługiwane na 3 zmianach pracują 7 dni w tygodniu. Codziennie wysyłamy wielotonowe ładunki do naszych lokalnych centrów logistycznych. Stamtąd towary trafiają do klienta nawet w ciągu 24 godzin.Jakość

Zapewniamy klientom jeden z najszerszych asortymentów w kraju. Ciągłe inwestycje w nowe produkty oraz maszyny do obróbki stali pozwalają nam konkurować z największymi firmami z branży metalurgicznej w Europie. Również uruchomienie działu obróbki skrawaniem (frezowanie, szlifowanie, wiercenie płyt) pozwoli na zwiększenie naszej konkurencyjności na polskim i europejskim rynku.Konkurencyjność

Jako pierwsza firma wśród dystrybutorów stali narzędziowych w Polsce, tworzymy własne laboratorium badawcze. Od wielu lat współpracujemy z kilkoma instytutamii ośrodkami badawczymi na terenie całego kraju. Każdego miesiąca zlecamy kilkadziesiąt wyspecjalizowanych badań metalograficznych, dzięki którym nasze produkty są pod stałą, ścisłą kontrolą technologiczną.